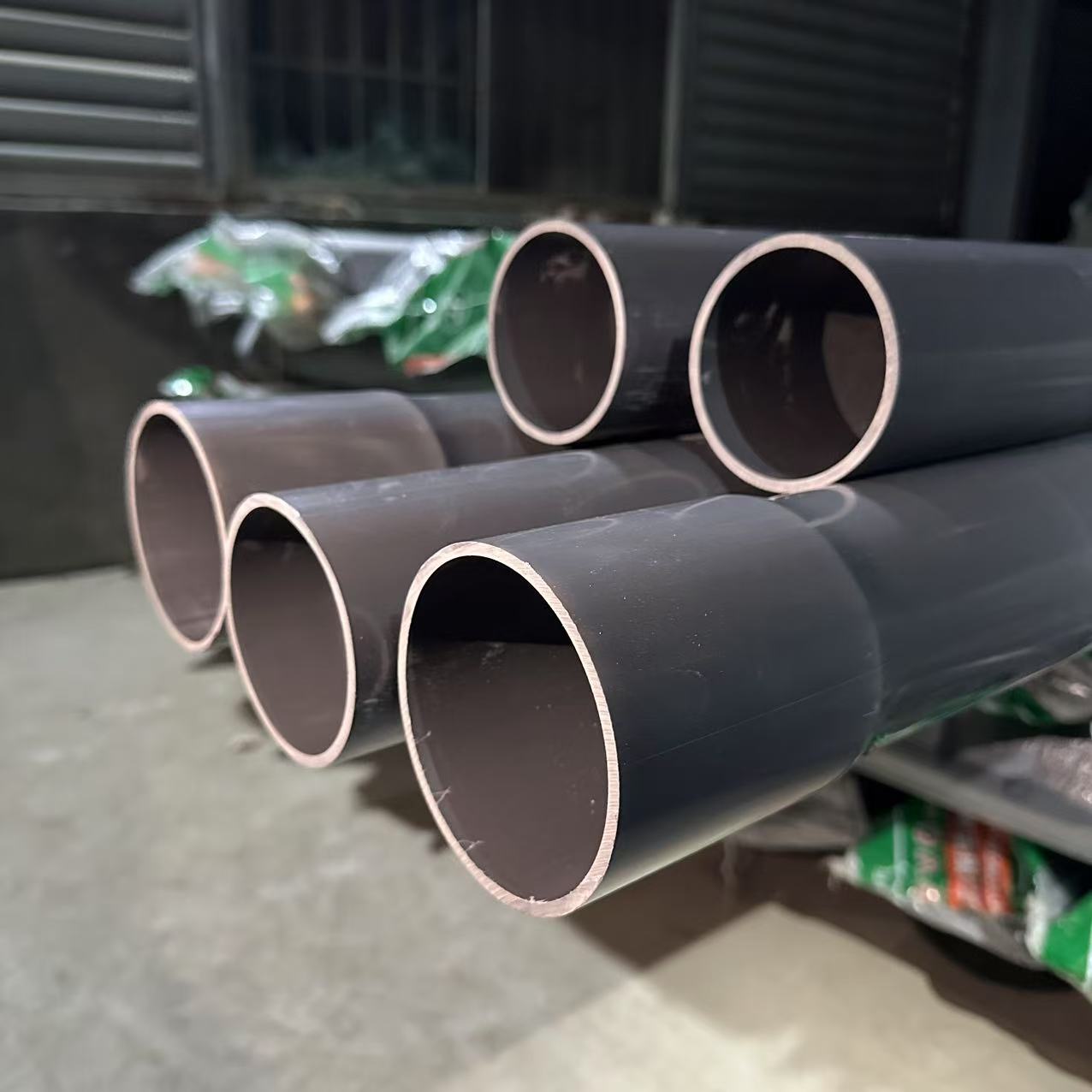

Introduction to UPVC Water Supply Pipe

1. Product Definition

UPVC water supply pipe, short for Unplasticized Polyvinyl Chloride water supply pipe, is manufactured by mixing polyvinyl chloride resin with stabilizers, lubricants, and other additives, and then processing through specific techniques. It is designed for transporting potable water and other types of water in various applications.

2. Product Features

Hygienic and Non – toxic

Made from polyvinyl chloride resin and additives that meet hygienic standards, the pipe ensures no contamination to the water quality. It complies with national drinking water hygiene standards, making it safe for transporting drinking water in daily life.

Excellent Corrosion Resistance

It shows good tolerance to most chemical substances. This allows it to operate stably under different water quality conditions, effectively extending the pipeline’s service life and reducing pipeline damage and maintenance costs caused by corrosion.

Good Weather Resistance

The pipe has certain resistance to ultraviolet rays and aging. Even when used outdoors for an extended period, its performance remains relatively stable. This makes it suitable for both open – air and buried water supply projects.

Good Mechanical Properties

UPVC water supply pipe has high compressive strength and impact toughness. It can withstand a certain amount of external pressure and vibration, ensuring the safety and stability of the pipeline during water supply.

Low Thermal Conductivity

With good thermal insulation properties, it can reduce heat loss during the transportation of hot water, thereby lowering energy consumption. This feature is especially beneficial for hot water supply systems.

3. Production Process

Similar to the production of UPVC drainage pipes, the process begins with thoroughly mixing selected polyvinyl chloride resin and additives. The mixture is then fed into an extruder, where it is heated and melted. After that, it is extruded through a die to form the shape of the pipe. During production, parameters such as temperature and pressure are precisely controlled to ensure the quality and performance of the pipe. Subsequently, through processes like cooling, sizing, traction, and cutting, UPVC water supply pipes that meet the standards are produced.

4. Product Specifications

The nominal outer diameter of UPVC water supply pipes generally ranges from 20mm to 315mm. The wall thickness is designed according to different nominal pressure ratings, with common nominal pressures including 0.6MPa, 0.8MPa, 1.0MPa, 1.25MPa, and 1.6MPa. These specifications can meet the requirements of different water supply pressures and flow rates.

5. Connection Methods

Hot – melt Connection

This method uses special hot – melt equipment to heat the connection parts of the pipe and fitting to a molten state. Then, they are quickly joined together with a certain pressure applied, forming a reliable and sealed connection. It is suitable for larger – diameter pipes.

Glue Bonding

For small – diameter pipes, a special PVC glue is applied to the connection surfaces of the pipe and fitting. The pipe is then rapidly inserted into the fitting socket. After the glue solidifies, a sealed connection is achieved. This method is simple and quick to operate.

6. Application Areas

• Urban Water Supply Systems: It is mainly used in municipal water supply networks and secondary water supply systems in residential communities.

• Industrial Water Transportation: Applicable for transporting cooling water and process water in industrial production.

• Agricultural Irrigation Systems: Can be used as water – conveying pipelines in agricultural irrigation projects.

Reviews

There are no reviews yet.