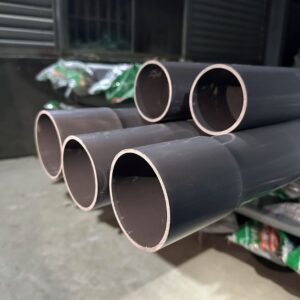

Product Features

- Light Weight: Its specific gravity is only 1/5 that of steel and cast iron pipes and 1/2 that of concrete. For pipes of the same specification and length, the weight is approximately 1/4 that of ductile iron pipes and 1/10 that of concrete pipes. The transportation cost can be reduced by 1/2 to 1/3.

- Strong Corrosion Resistance: It has excellent resistance to corrosion by chemical substances such as acids, alkalis, and salts, and is suitable for various harsh chemical environments.

- Low Flow Resistance: The inner wall is smooth, with a roughness coefficient of 0.008 – 0.009. Its water conveyance capacity is 20% higher than that of cast iron pipes and 40% higher than that of concrete pipes.

- High Mechanical Strength: The tensile strength at 23 °C is not less than 45 MPa. It has good compressive resistance and will not break when compressed to half of its outer diameter. It can withstand certain external pressures and impacts.

- Hygienic and Non-toxic: It adopts an environmentally friendly formula and will not cause secondary pollution to the irrigation water quality, ensuring a safe growth environment for crops.

- Long Service Life: Under stable temperature and pressure conditions, the service life is not less than 50 years.

- Easy Installation: It is light in weight and has a certain degree of flexibility. It is convenient to connect, has low construction difficulty, and can save labor and time costs.

- Easy Maintenance: The maintenance cost is only 30% of that of ductile iron pipes or concrete pipes.

Production Process

Generally, PVC resin powder and additives are uniformly mixed in a mixer according to a certain proportion. Then, the mixed materials are fed into an extruder, heated and melted, and extruded through a mold to form a pipe blank. After that, processes such as sizing, cutting, and flaring are carried out to make the finished product.

Product Specifications

The nominal outer diameter is usually between 63 mm and 630 mm, with common ones being 63 mm, 75 mm, 90 mm, 110 mm, etc. The pressure grades include 0.2 MPa, 0.25 MPa, 0.32 MPa, 0.4 MPa, etc.

Connection Methods

- Solvent Adhesion: Special solvent glue is applied to the connection parts of the pipes and pipe fittings. After the solvent evaporates, a firm adhesion is achieved.

- Elastic Rubber Sealing Ring Connection: The rubber sealing ring is installed in the groove of the socket of the pipe. When the pipe is inserted into the pipe fitting, the rubber ring is compressed to form a seal.

Application Areas

It is mainly used in the field of agricultural irrigation, such as drip irrigation, sprinkler irrigation, and micro-irrigation systems. It is also suitable for low-pressure water conveyance and irrigation projects, as well as for garden irrigation and greenhouse irrigation.

Reviews

There are no reviews yet.